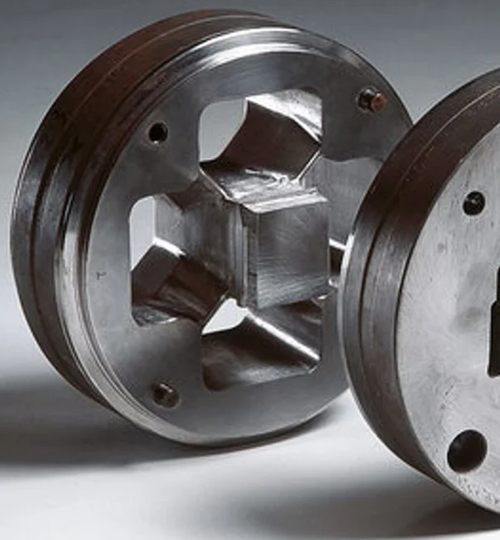

Carbide Precision Dies and Tools

Carbide precision dies and tools are critical components used in high-accuracy manufacturing processes. These tools are typically made from tungsten carbide, a dense, extremely hard material known for its durability and wear resistance.

Types of Carbide Precision Dies and Tools

- Carbide Dies

- Wire Drawing Dies: Used for reducing the diameter of wires through a series of drawing operations. Tungsten carbide allows for minimal wear and long operational life.

- Cold Heading Dies: Employed in forming metal parts at room temperature, particularly in the production of fasteners like bolts and screws.

- Extrusion Dies: Used to shape materials (metals or polymers) by forcing them through a die to produce a continuous profile.

- Carbide Tools

- Cutting Tools: Carbide-tipped or solid carbide tools are used for turning, milling, drilling, and boring operations. They offer exceptional edge retention and heat resistance.

- Punches and Inserts: These are used in stamping and forming operations, designed to withstand high-impact and abrasive conditions.

- Forming Tools: Custom-shaped carbide tools are utilized to shape or form parts with high precision.

Advantages of Using Carbide

- High Hardness and Wear Resistance: Ensures longer tool life and consistent performance.

- Heat Resistance: Allows tools to maintain integrity and cutting performance at high operating temperatures.

- Dimensional Stability: Maintains accuracy and tolerances during prolonged use.

- Reduced Downtime: Longer-lasting tools mean fewer replacements and less machine downtime.

Applications

- Automotive Industry: For manufacturing engine parts, transmission components, and structural fasteners.

- Electronics: In the production of precision connectors, semiconductor packaging, and micro-components.

- Aerospace: For components requiring tight tolerances and exceptional material strength.

- Metal Forming and Stamping: Used in high-speed, high-pressure applications where precision and tool life are critical.

Custom Carbide Tooling

Many manufacturers offer custom carbide dies and tools tailored to specific production needs. These custom tools are designed using CAD/CAM technology and manufactured through advanced grinding, EDM, and polishing processes to achieve optimal performance.

We Provide the Best Service in Industry

Discover how we can help you achieve your goals. Our experts are here to listen, guide, and provide actionable solutions