Rock Drill Tools

Rock drilling tools are specialized equipment and components used to drill into hard rock formations in applications such as mining, construction, tunneling, quarrying, and oil & gas exploration. The tools are designed to break, cut, or crush rock efficiently and withstand extreme conditions.

Types of Rock Drilling Tools

1. Drill Bits

These are the cutting tools at the end of the drill string.

- Button Bits: Have tungsten carbide buttons; used in hard rock.

- Chisel Bits: Used for softer rock and shallow drilling.

- Cross Bits: Have a cross shape; suitable for medium-hard rock.

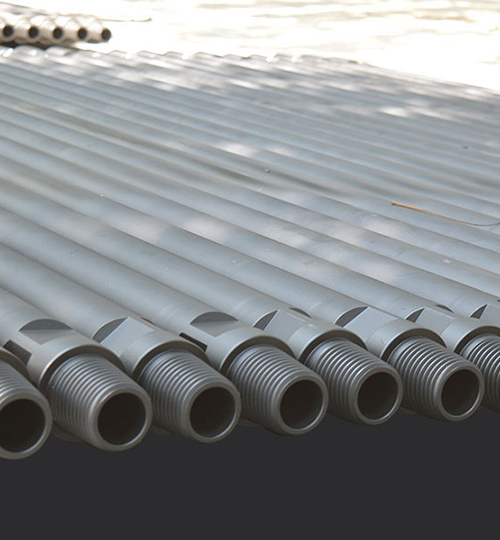

2. Drill Rods

- Connect the drilling machine to the bit.

- Transfer rotation and impact energy.

- Can be hollow (for air/flushing fluid) or solid.

3. Shank Adapters

- Connect the drill rod to the rock drill.

- Transfer impact and rotation forces from the machine to the drill string.

4. Coupling Sleeves

- Connect two drill rods together in long hole drilling.

5. DTH (Down-the-Hole) Hammers

- Pneumatic hammers that sit directly behind the drill bit.

- Used for deep hole drilling and hard rock.

- Delivers powerful impact directly at the drill bit.

6. Top Hammer Tools

- Impact force is generated by a hammer outside the borehole (on the drilling machine).

- Used for shorter holes and less hard formations.

🛠️ Applications

- Mining: Blasting holes, exploration, production drilling.

- Construction: Foundation drilling, anchoring, tunneling.

- Oil & Gas: Exploration drilling (although typically more advanced rotary tools are used).

- Geothermal & Water Wells: Deep hole drilling into bedrock.

🧱 Materials Used

- Tungsten Carbide: Extremely hard; used in cutting tips.

- High-Strength Steel: For rods and shanks; resists wear and impact.

- Alloy Steel: Heat-treated for toughness and fatigue resistance.

⚙️ Drilling Methods

- Percussion Drilling: Repeated hammering action breaks rock.

- Rotary Drilling: Bit rotates to grind away rock.

- Rotary-Percussion (Combined): Common in hard rock drilling.

✅ Factors to Consider When Choosing Rock Drilling Tools

- Rock hardness and abrasiveness.

- Hole depth and diameter.

- Drilling method (top hammer vs DTH).

- Cost-effectiveness and wear resistance.

- Bit shape and button configuration.

We Provide the Best Service in Industry

Discover how we can help you achieve your goals. Our experts are here to listen, guide, and provide actionable solutions